Products

NC-BASE

THE PROFESSIONAL CHOICE FOR CNC PROGRAM MANAGEMENT

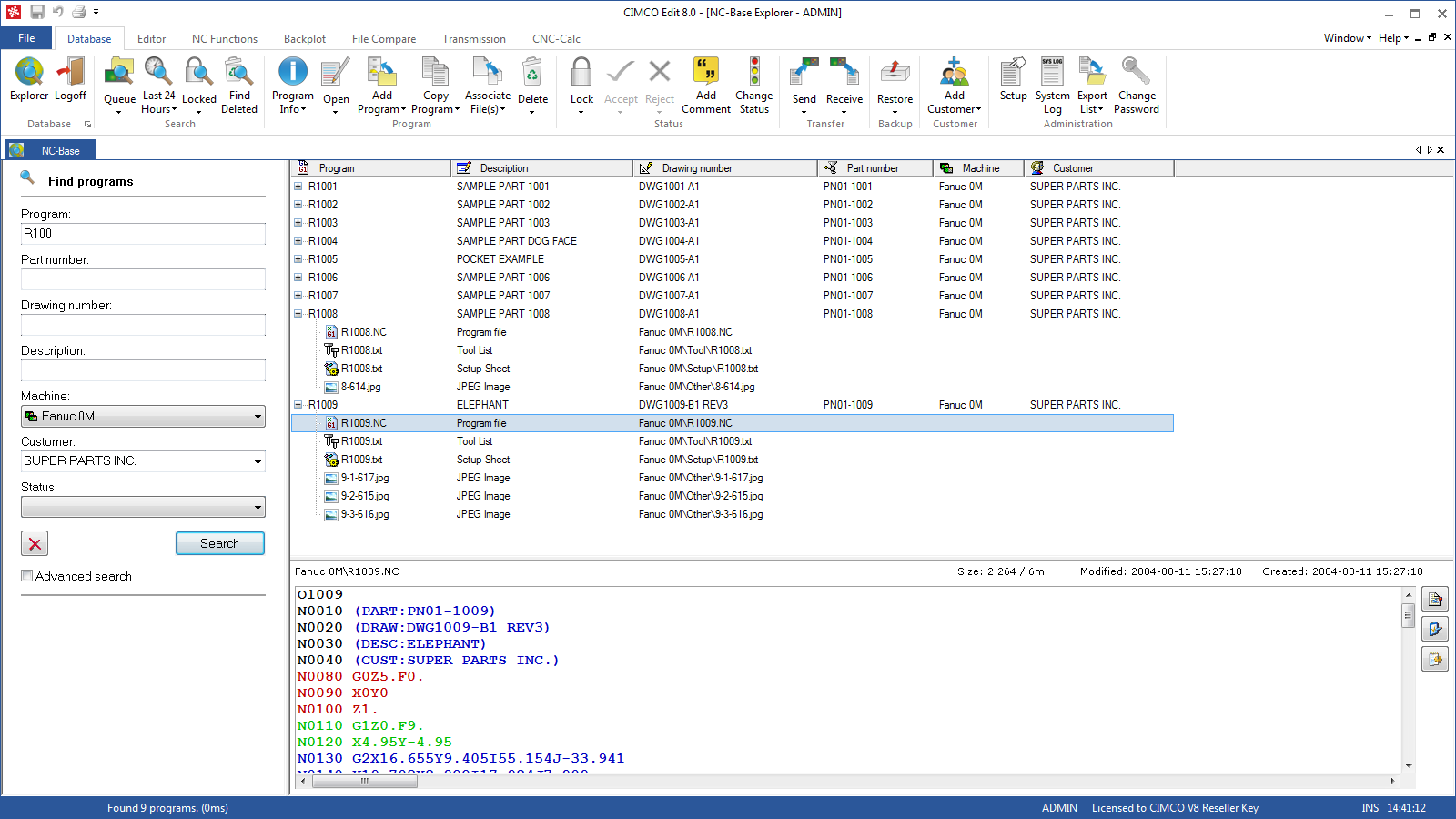

CIMCO NC-Base is a CNC program management tool that allows you to organize and manage your CNC programs and related production documents.

Management of part programs and associated production documents is often a time consuming task for CNC programmers and operators. CIMCO NC-Base takes care of that job and goes one step further. By providing an integrated and highly flexible management, search and editing environment, programmers and operators are guaranteed to work more effectively.

INFORMATION MANAGEMENT

Achieving product and quality goals today requires that the correct information and data get to the right individuals and equipment as efficiently as possible. NC-Base is the CNC program management tool that allows you to organize and manage your CNC programs and related production documents most effectively through the use of a reliable and fast SQL relational database.

PRODUCTION CENTRIC

CIMCO NC-Base is production centric, designed to be used by people in the programming department and on the shop floor. With NC-Base CNC programmers and production staff can assemble virtual folders containing all the necessary data used by machinists, operators, quality staff, and others who are responsible for finished parts.

SEND ANY DOCUMENT TO THE SHOP FLOOR

Why just send CNC programs to the shop floor when you can also provide setup sheets, tool lists, images, and other vital information required to manufacture parts? This information may be accessed from PCs running the NC-Base Client or printed out for manual distribution. Either way, NC-Base helps ensure the right part gets made right every time.

UPDATE AND ACCESS DOCUMENTS EASILY

CNC operators can access and update the database directly from the CNC control, or any PC on the shop floor.

FEATURES

Powerful SQL Database Engine

Powerful SQL Database Engine capable of handling hundred of thousands of programs and their associated production files.

Comprehensive Search Functionality

Comprehensive Search Functionality modeled after the standard Microsoft search tool but enhanced for CNC program searching.

Customizable Data Fields

Customizable Data Fields of up to nine (9) user-definable fields are available to categorize and manage programs the way the customer wants.

Production Document Management

Production Document Management is provided where customers can associate all forms of production documents with their CNC programs including setup sheets, tool lists, memos, inspection notes, image files, etc. Includes integrated image viewing (for standard file types) and the ability to launch external applications and/or editors for viewing of proprietary or specialized file formats.

File Templates

File Templates are provided for setup sheet, tool list, and memo. This feature automatically creates the files, based on templates you create in CIMCO Edit, MS Word, an HTML editor, etc.

Backup Controls

Backup Controls provide flexible and configurable backup capabilities including backup single and multiple files, restore, and compare.

Approval Controls

Approval Controls allow programmers to mark files as approved or unapproved thereby limiting access for communications. An approval queue also offers a quick tool for programmers to see which files, if any, are present in a queue to be reviewed for approval.

Version Controls

Version Controls allow programmers total control and flexibility over file versioning including the capability to compare updates with originals and in-process edits – and handle the changes accordingly.

Locking Controls

Locking Controls allow programmers to lock files to control editing and communication access.

User/Group Management

User/Group Management – Rights Controls are designed into NC-Base allowing you to limit access and control what each individual user or group is able to work with inside the NC-Base Client.

Machine Groups

Machine Groups allows administrators to create groups for machines/ports for association with part programs. Works with CIMCO Edit Professional.

DNC Communication

DNC Communication using CIMCO Edit or DNC-Max. Users are then able to initiate ‘send’ transfers from within the NC-Base Client interface.

Automated Import

Automated Import eliminates the need for programmers to manually input programs during the initial installation or as programs are created inside CIMCO Edit or auto-received from DNC-Max.

Integrated with CIMCO Edit 7

Integrated Interface Inside CIMCO Edit allowing customers to work within one environment for both editing and managing their CNC programs and associated documents.

Ethernet (Networked) Control Support

Ethernet (Networked) Control Support includes support for auto-import of programs into NC-Base when saved off from networked (TCP/IP, etc.) CNC controls

Seamless Integration with DNC-Max

Seamless Integration with DNC-Max is available, extending the capabilities of both systems for the most advanced, automated file management anywhere