CIMCO Software Suite

Scheduler

Production scheduling and order tracking

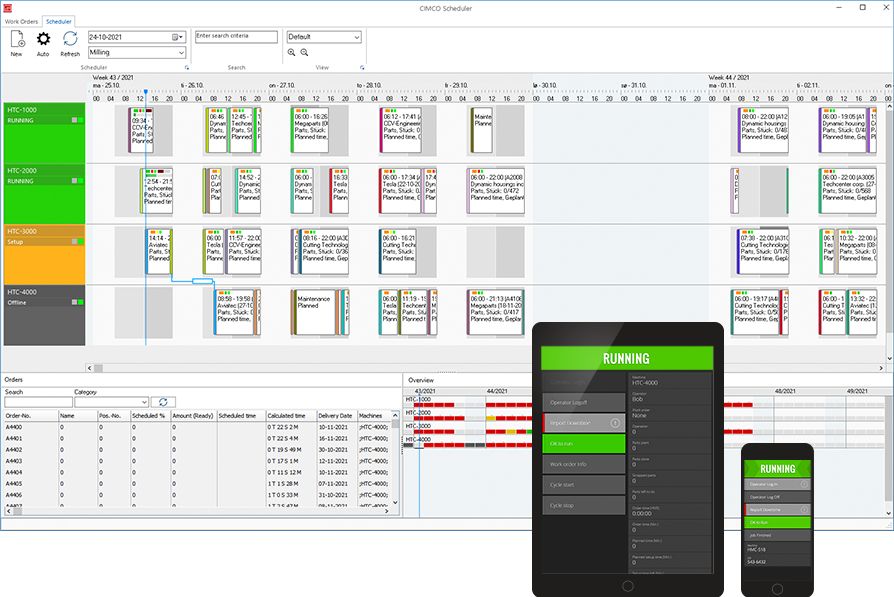

CIMCO Scheduler is the production scheduling and order tracking solution that helps customers increase the accuracy of delivery dates, identify untapped production capacity, and allows for planning of preventative maintenance.

Shop floor driven

CIMCO Scheduler provides a central planning board that is driven by real-time data from the shop floor.

Using a specialised mobile interface, machine Operators can provide status updates about orders and machines, which is then instantly reflected in the main planning software and digital signage such as Live Screens and Dashboards.

Benefits

Manage all orders in one application

Easily plan, organise, and track all your planned orders in one application that's driven directly by the actual activities on your shop floor.

Increase delivery accuracy

Increase the accuracy of delivery dates with a complete real-time overview of all your planned orders, machine capacity, shifts, and more.

Real-time order status

Follow the status of orders in real-time and instantly see the consequences of machine downtime on dependant and following orders.

Eliminate production bottlenecks

Get an overview of your machines' capacity, multi-machine orders and dependencies to avoid bottlenecks and costly downtime.

Identify untapped production capacity

Get the most out of your machines and production by knowing exactly when your machines are being used.

Allows for preventative maintenance

Know when to schedule machine maintenance to avoid critical downtime when it's time to deliver.

Features

Timeline-based

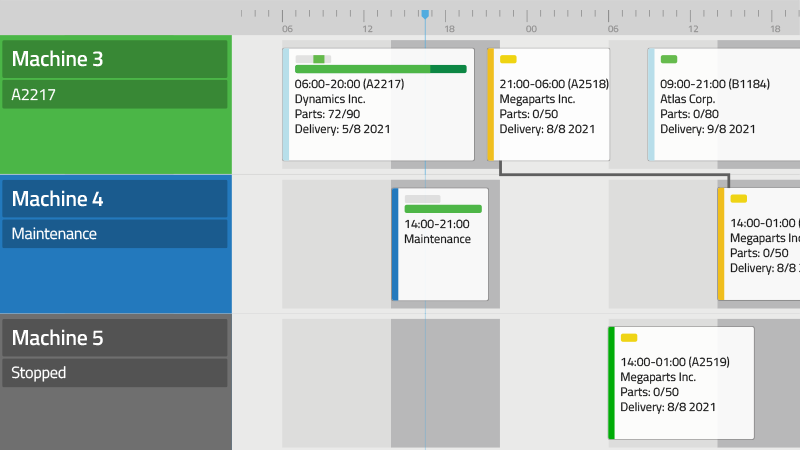

Timeline-based overview of machines, orders, and dependencies over several weeks. Each machine has its own row with machine status, orders and shifts. Dependencies are shown as lines between orders.

Order status at a glance

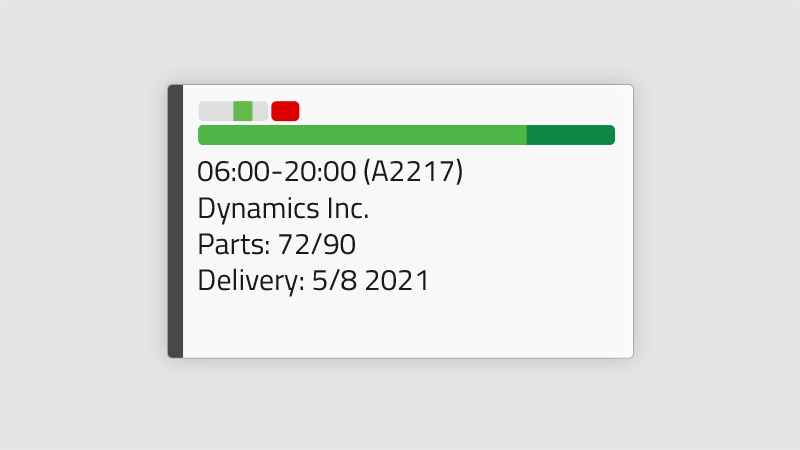

Real-time overview of order and machine status. Orders have indicators and progress bars to show the status of operation, material availability, and delivery. Information can be directed to TV screens for open space monitoring and digital signage.

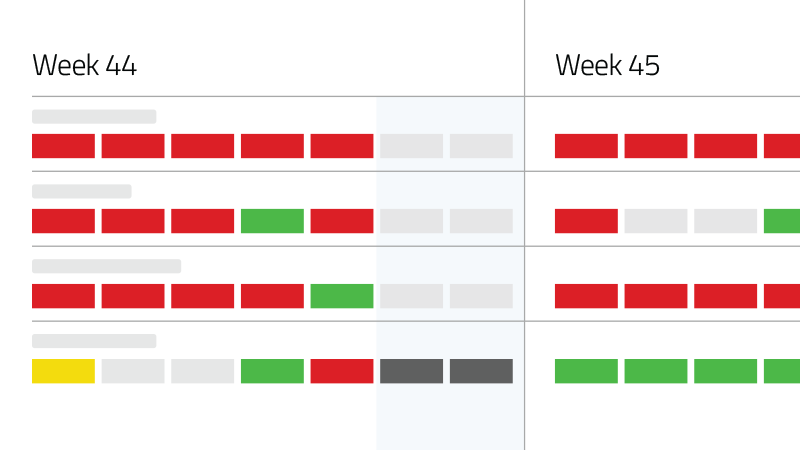

Machine capacity overview

View the available production capacity for all your machines over weeks and months. Each day is colored to indicate available capacity.

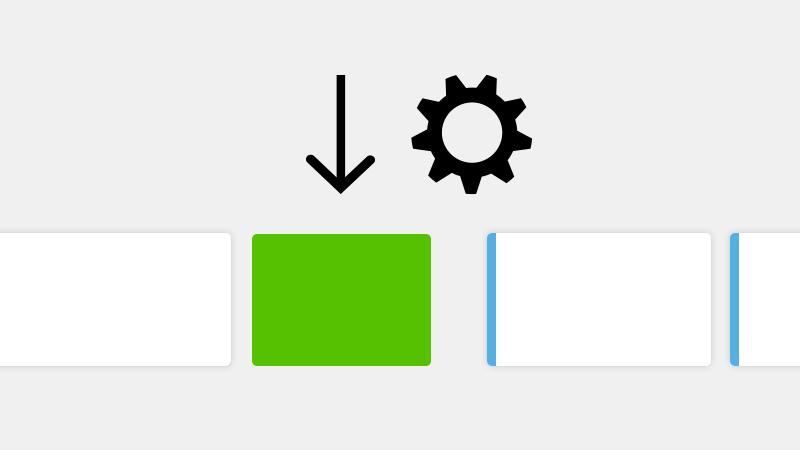

Automatic scheduling

Auto-schedule orders by either placing new orders after the last one scheduled or by placing them further ahead where there is available capacity. Start and end dates can be simulated before scheduling for production.

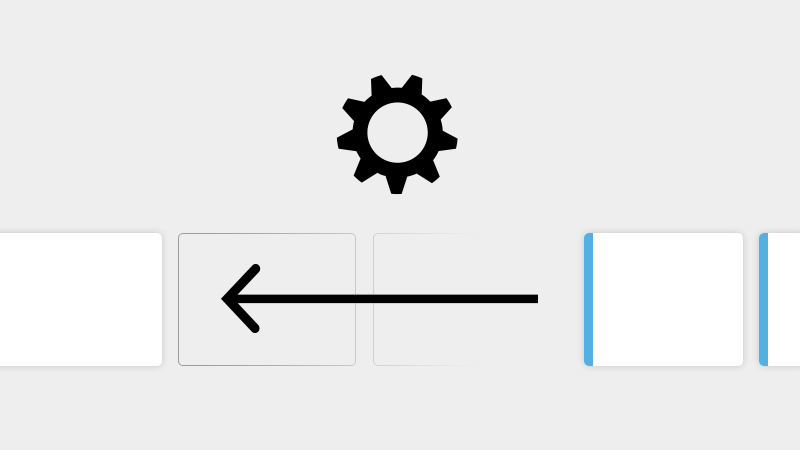

Rescheduling orders

Modify or delete orders directly from the Timeline or drag-and-drop orders between machines. The consequences of a change are presented for approval before an order, and any affected orders, are automatically rescheduled.

Operator interface

Update order and machine status directly from the shop floor with the Operator interface. Display key order data, start/stop orders, set machine status, or enter reasons for downtime.

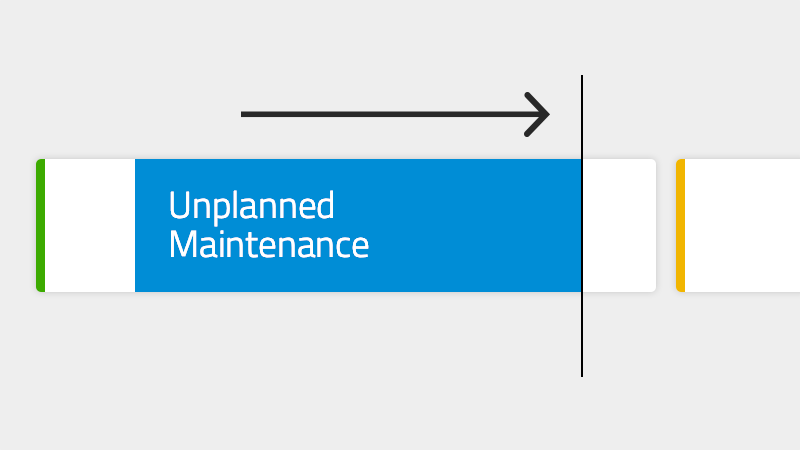

Maintenance

Schedule Planned Maintenance similar to orders. If the system is notified that a machine is down, Unplanned Maintenance is auto-inserted in the Timeline and the remaining part of an order, and subsequent orders, are pushed back.

Reports

Create custom reports from your order data with the template-based reporting system. Reports can be printed or exported, and templates can be customised with the desired information, layout and style.

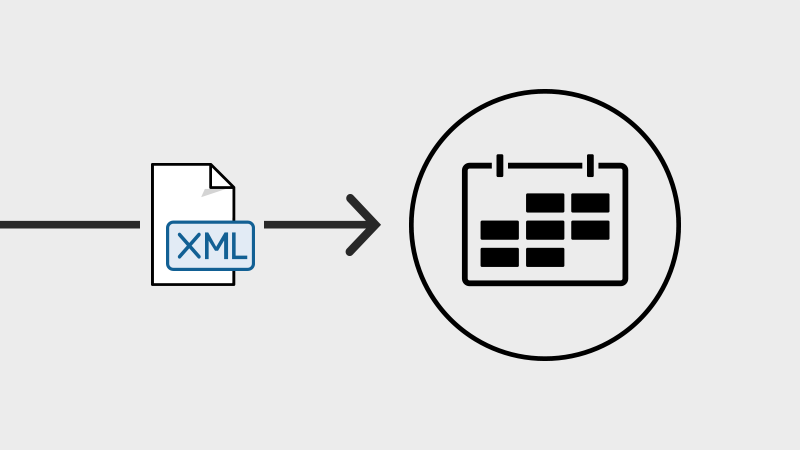

Import orders

Auto-import orders from an external system such as an ERP system (using XML formatted data). Use the automatic scheduling feature to quickly simulate and schedule imported orders.

ALL FEATURES

Visual planning board / Timeline

Graphical timeline

The Timeline provides an overview of time, machines, scheduled orders and order dependencies over several weeks. The timeline is structured with a horizontal calendar running on top and a row for each machine that shows the machine's status* and the orders scheduled for that machine and their status. Shifts are indicated in the background of each machine's row.

Timeline navigation / Search

Easy selection of which group of machines to view. Navigate the Timeline with zoom in/out, mouse-scroll or view a predefined period of time such as the next 5 days. Jump directly to an order with the search option.

Customised views

Customise your own Timeline views. Configure which elements to show, the hight/width of machine rows, how orders should look and more.

Orders on the Timeline

Orders are shown as colored boxes that each contain key information about the order as well as its current status. Order dependencies are visualised as lines between orders and orders are always placed on the machine (row) that will be used to manufacture the order.

Individual shifts for each machine

Individual shifts can be configured for each machine row.

Integration of national holidays

National holidays are included.

Order and capacity overviews

CIMCO Scheduler presents an overview of unplanned orders and an overview of available production capacity. For easy access, these overviews are positioned in the bottom part of the interface, below the Timeline.

Unplanned orders overview

A list of all unplanned orders that can be searched and sorted as needed. These are orders that have not yet been scheduled for production. Orders can be planned by simply dragging them onto the Timeline.

Capacity overview

The capacity overview shows the available production capacity for each machine during the next 4-5 weeks. A specific color is assigned to each day where red days equal no capacity, gray days equal full capacity (free) and green days equal medium capacity.

Planning of orders

Order and Operations

An order is made up of one or more Operations that can each be assigned to a specific machine. An Operation can also be marked as "External" which means it will not be scheduled, but will impact the total time of the order. This can be an external operation such as hardening or other operation/process that must be taken into account.

Operation dependencies

Dependencies describe the relationship between Operations in an order and the sequence in which Operations will be completed. Dependencies are also used when an order or operation must be rescheduled. A line between Operations in the Timeline indicates a dependency.

Real-time order status

Only orders that are marked "Approved for Scheduling" can be scheduled/planned on the Timeline. An order/operation box on the Timeline contains key information and has several real-time status bars to provide an overview at a glance: 1. Status of operation: as expected / better / behind 2. Status of material: available / not delivered 3. Status of delivery: in time / close to exceeding delivery date / delivery date exceeded 4. Operation progress: progress bar based on num. of parts done The color of the order/operation top bar indicates whether it is not started, started or finished.

Custom information and color

Both the background color and the information displayed in an order/operation is fully customisable such as displaying Start-end time, Customer name, Number of parts, Duration and more. Data such as Parts done is updated in real-time.

Reuse information for recurring orders

Data from previous orders such as order time, setup time, and downtimes are stored in the systems database and can be reused for recurring orders. This makes it convinient and fast to schedule new orders.

Planned and unplanned Maintenance

Planned maintenance can be scheduled similar to orders. Unplanned Maintenance, however, is automatically inserted in the Timeline the moment an Operator notifies the system that a machine is down. Unplanned Maintenance splits the current order and pushes the remaining part of the order, and any following orders, back in time until the order is resumed.

Automatic scheduling / Simulation of orders / Import (ERP)

Automatic scheduling and simulation

CIMCO Scheduler comes with the ability to auto schedule orders and can simulate the start and end dates of orders before they are scheduled and placed on the Timeline. Orders can be auto scheduled in two ways; by simply placing the new order after the last one scheduled or by placing the new order further in the future at a point with plenty of free production capacity.

Automatic import from external systems

Orders can be auto imported from an external system such as an ERP system (using XML formatted data). With the help of the auto scheduling feature in CIMCO Scheduler it becomes an easy workflow to take one or more imported order, simulate their start and end dates, make adjustments if needed, and approve them for scheduling/production.

Rescheduling orders / Drag and drop

Update and auto reschedule orders

All the key information of an order can be updated directly from the Timeline and orders can be drag and dropped from one machine to another. Modifying key information, such as changing the number of planned parts or moving an order to a different machine, will auto reschedule the order itself and any affected orders. When a change affects other orders, CIMCO Scheduler shows all the consequences of the change in a dialog for the user to approve. Rescheduling of affected orders can be disabled if needed.

Automatically adjust orders

CIMCO Scheduler allows you to configure how and when auto rescheduling should occur. Set the end-time tolerance before an order is auto rescheduled, set the amount of time that is added to orders that exceed delivery/end date, set if delivery date of stopped jobs should be recalculated when started again and more.

Dedicated Operator interface (PC and mobile)

The Operator interface (also referred to as the Operator Screen) is a modern, browser-based client that works on any mobile device such as a tablet, smartphone or smart TV. The interface is used at the machine to display order information, initiate orders and set reasons for downtime/stops. Use-cases such as having a tablet mounted at every machine or managing multiple machine-specific Operator interfaces from a single mobile device are fully supported. All data in the interface is updated in real-time without any browser-reloading and all clients can be auto updated from a central point. Supports both a bright and dark theme.

Login

Login can be enabled for users of the Operator interface. For both security reasons and for user identification and logging.

List of orders / Order start and stop

The Operator interface displays a sorted list of upcoming orders for the machine. An order is started by simply tapping on it and the machine and order's status is updated in CIMCO Scheduler.

Order information and order status

Key information about the current order is displayed in real-time such as Number of items, Order time, Progress, Delivery date, and more. The information shown can be customised.

Downtime reasons

Enter machine downtime directly from the Operator interface such as Waiting for Setup, Waiting for Maintenance, Scrapped Part, Inspection and more. The remaining order is automatically recalculated and updated in CIMCO Scheduler when the order/job is resumed. Downtime reasons is optional and can be fully configured.

Digital signage / Monitoring

Because CIMCO Scheduler is built on the same software foundation as our Manufacturing Data Collection solution, CIMCO MDC-Max, it can take advantage of the same software components such as Live Screens, Dashboards, Shop Floor Screens, reporting and more. However, it is important to note that CIMCO Scheduler does NOT require any MDC connections to the CNC machines. This is only relevant if you wish to show real-time machine status and collect data for analytics and reporting on the performance of your machines.

Live screens

Use Live Screens to visualise the status of running orders and machines* in real-time. Machines are listed top to bottom with dedicated colors that clearly indicate the state of each machine. Colors can be set to flash on critical states and smaller notification/alert lights can be displayed by each machine. Live Screens are entirely customisable and can be displayed on large TV monitors as digital signage or on any mobile device.

Dashboards

Use Dashboards for real-time order data and performance tracking. Dashboards provide an overview of your real-time production data and KPIs at a glance. Dashboards can be displayed on large TV monitors as digital signage or on any mobile device.

Shop Floor Screens

Shop Floor Screens provide a bird's eye view of your entire shop floor and enable you to see the status of all your machines* (and current orders) based on where they are located. The color of machines change based on their state and smaller notification/alert lights can be displayed by each machine. Select any machine to get detailed information such as KPIs, current operator/order and other relevant information. Shop Floor Screens can be displayed on large TV monitors as digital signage and can be viewed and customised on any tablet or smartphone.

Customer management

CIMCO Scheduler includes basic functionality for managing customers and storing key customer information such as name, address and contact person. Customers are associated with orders which makes it easy to see which customer an order belongs to.

Reporting

Reports from order data

CIMCO Scheduler comes with a flexible template-based reporting system. Specify a few criteria such as time period, Machine Group, and which template to use and CIMCO Scheduler generates a report that can be printed or saved. More elaborate search criteria are also supported for generating advanced reports.

Templates

Create custom report templates that define the visual layout of reports as well as what data to extract from CIMCO Scheduler and its underlying database. Custom reports require coding knowledge.

Reports Dashboard

With the Dashboards feature in CIMCO Scheduler you can show multiple reports simultaneously for quick access and easy overview. The criteria of each report (time period, Machine Group, ect.) can be changed directly in the Dashboards interface.

Advanced reporting with Manufacturing Data Collection (optional)

Because CIMCO Scheduler is built on the same software foundation as our Manufacturing Data Collection solution, CIMCO MDC-Max, it can take advantage of the same software components including the advanced reporting capabilities in CIMCO MDC-Max.

Security

User/Group permission management system

Fine-grained control over User/Group permissions such as who can schedule orders, change orders, what machines users can access and so forth.

System components

Scalable architecture

CIMCO Scheduler is built on CIMCO's proven client/server and database software. It's a highly scalable solution that can benefit both small shops and corporate enterprises with machines in multiple remote facilities. System software can run on a single PC or, for enterprise requirements, be distributed on multiple servers with an unlimited number of PCs and Web Clients connected. Please note that the system is adapted to your company's specific requirements and as such the features available depends on your requirements and license type.

CIMCO Scheduler

The main PC application that provides a central digital planning board where production orders can be planned out, organised and tracked in a timeline-based environment. The application includes time-saving features such as automatic rescheduling of orders, order dependencies, import/export of order data and more. See below for all the details.

CIMCO MDC-Max Server

Robust and reliable server app lication that operates a fast SQL database (or Microsoft SQL, PostgreSQL). Does all the heavy lifting in the background such as processing incomming data, updating reports, communicating with external systems and distributing monitoring data to Live Screens, Dashboards, Operator Screens, etc. Features available depends on your requirements and license type.

CIMCO MDC-Max Web Client (mobile client running the Operator interface)

Modern browser-based webclient that works on any (modern) mobile device such as a tablet, smartphone or smart TV. Enables remote access to Operator Screens, Dashboards, Live Screens and Shop Floor Screens. Data is updated in real-time without any browser-reloading and all clients can be updated from a central point. Supports both a bright and dark theme. Features available depends on your requirements and license type.

CIMCO DNC-Max (port configuration)

Machine port configuration and management is handled by our powerful DNC communications software CIMCO DNC-Max which also provides features such as advanced program transfers, Remote Request, dynamic feedrate and spindle speed adjustment, auto-receive, parameter offsets and much more. Features available depends on your requirements and license type.